ProShip Senior Sales Engineer, Clint Boaz, shares the why and how behind intelligently stored commodity data.

Written by Clint Boaz, Senior Sales Engineer and Shipping Expert at ProShip, Inc.

“Before anything else, preparation is the key to success.” – Alexander Graham Bell. ProShip shipping experts have been preaching preparation for peak since January of this year. This preparation should include a thorough review of your carrier mix to ensure that you have the flexibility to diversify when faced with capacity or pricing constraints. It should also include a review of your commodity data and easy access to that data, confirming it is efficiently stored and organized.

If your business ships hundreds or thousands (or even millions) of packages a day, this storage and organization will be crucial for peak times – even more so if some of those shipments are Dangerous Goods. ProShip supports organizations every day whose operations are hindered by a lack of access to their own data. The partnership with Labelmaster is all about getting that data organized so businesses can ship hazmat safely, compliantly and efficiently.

So what specific data do you need to have? Answer: All the information that is relevant to whatever it is being shipped. Data can be as basic as weights and dimensions, or it can include ingredients, components, chemical makeup, special handling information, units of measure and a dozen other data points. If the shipment involves hazardous materials, that information can also include a U.N. ID number, proper shipping name, hazard class, packing group, packing instructions and test summary data, among other data points. Data is an indispensable step in streamlined shipping, especially when there’s hazmat involved. [See: Hazmat Process Model]

This data is most likely stored somewhere – most enterprise-level operations have the ability to store information about their SKUs. However, some simply do not have that data stored or organized in a way that ProShip software can use it. That data can be in an ERP or in a WMS – or it can be in the parts repository in Labelmaster’s DGIS software, an excellent place to store this information. The key is that it has to be somewhere for Proship software to work properly. This is the difference between processing a lithium battery shipment in seconds and having a chart duct-taped to your wall with 18 steps for shipping a lithium battery.

Without that organized product commodity data, ProShip multi-carrier shipping software is unable to support the fastest shipping speeds or maintain carrier compliance, two essentials for building stronger customer revenue streams. To compete in the post-pandemic e-commerce explosion, it is crucial to provide speedy deliveries while keeping costs in line. ProShip takes speed and cost reduction to a whole new level. [View the ProShip Integrated Labelmaster Add-On Brochure]

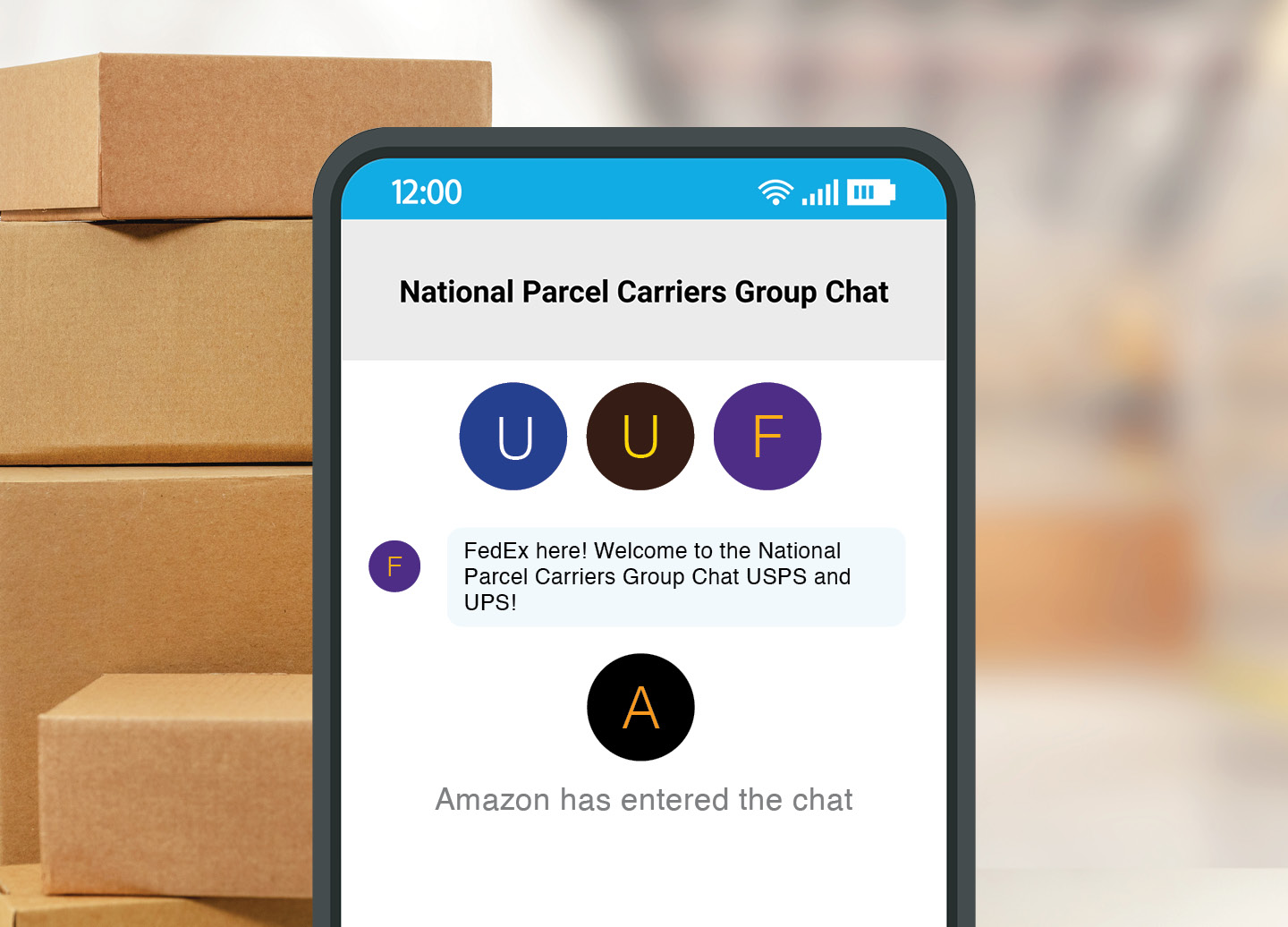

ProShip software isn’t just an API—it’s an engine with the ability to connect to any host system, e-commerce site or warehouse technology. The ProShip solution works directly with all carriers in one centralized server solution, with rates hosted and updated directly on our server – rating and labeling in milliseconds.

Except – these benefits aren’t available if your data’s a mess. By the same token, having complete, accurate master data is the key to streamlining compliant hazmat transport with Labelmaster’s DGIS. To ship something that’s hazmat in ProShip the data is passed through the ProShip software to avoid double keying and manual entry errors. Without that data, you are at a distinct disadvantage.

Collecting and organizing your commodity data, unfortunately, is a large undertaking—but ultimately incredibly important preparation for managing peak shipping or just a post-COVID surge in shipping. The larger the organization, naturally, the bigger job it becomes. If a startup is shipping only 50 packages a day, now is the perfect time to collect and organize your data—before that 50 becomes 500 or 5000. Without organized data, weak processes will likely slow your growth. Getting it organized now can turn a 12-step processes into a 3-step processes.

No matter the size, getting started it he first step. Here are a few important tips:

- Stay the path: It may be a long and tedious process, but it is possible as long as there is commitment.

- With this in mind, the project probably shouldn’t be handed over to an intern: The project manager should lead with familiarity of the regulations and requirements. If hazmat’s involved, someone who’s been trained and

certified is ideal. - Start with the most shipped products: The smallest effort can make the biggest impact when you start with the most shipped products. Next, go after the lowest-hanging fruit and notch short-term wins. Anything is better than nothing.

- Call Labelmaster for help. Labelmaster has expertise in what you have to provide and where to find it, matching up what you have available in safety data sheets with where you can store it.

In today’s shipping environment, success is all about speed, reliability and confident compliance. If you don’t have your data collected and organized, the process can be minutes long. ProShip strives for seconds and there’s huge value associated with that difference.

Back to Blog

Back to Blog